1

/

of

6

DATD AUTO TIP DRESSER

DATD8268-NC NOZZLE CLEANER

DATD8268-NC NOZZLE CLEANER

DATD8268-NC

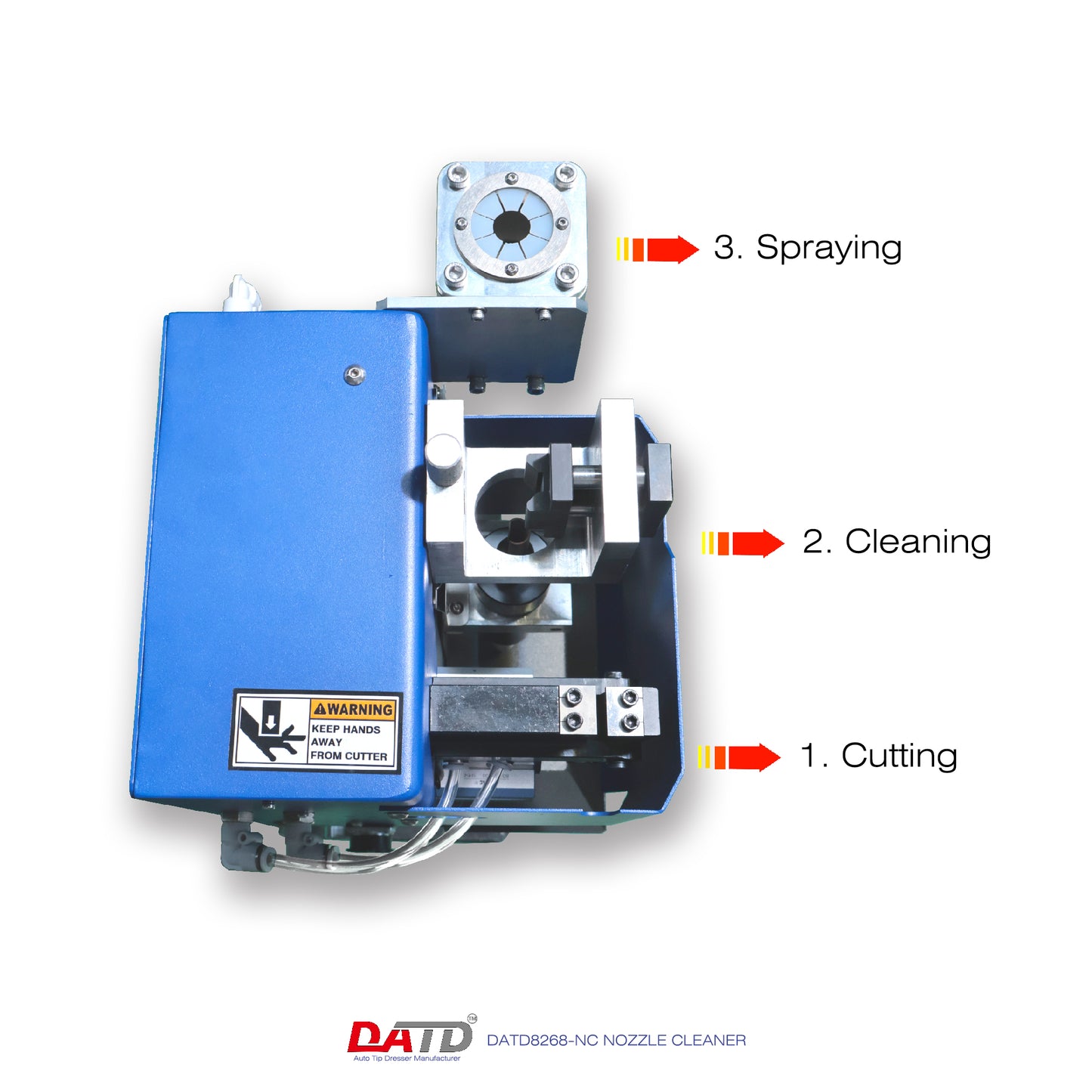

1. The workstation of cut wire, cleaning gun and oil sprayer are arranged separately

2. The gun cleaning station has a dismountable pedestal (optional); the duplex pieces of gastreatment can be mounted on the pedestal or main engine of welding gun cleaner;

3. Applicable to spot weldrs of all brands; control signal: 24V DC; gas pressure: 0.4~0.8MPa

4. 1.6mm carbon steel welding wire can be cut off easily at the air pressure of 0.3MPa thanks tothe intensified design of wire cutting structure; insensitive to air pressure fluctuation.

5. The cut wire blade can be mounted at either front and revers side; so, the other side can beused normally when one side is worn, in order to prolong the blade service life and reduce use cost.

6. The oil sprayer, which is right below the welding gun during operation, can spray mist anti-.splash oil evenly into the welding gun. The oil film can reach the bottom of electric nozzle.

7. The oil sprayer is sealed to avoid polluting the environment. lt is fited with oil return device bydefault, in order to recycle the residual anti-splash oil and reduce use cost.

8. The reamer has undergone high-quality alloy steel nitriding treatment, to ensure good tenacitywhile keeping surface hardness above HRC56, and keep it sturdy and durable.

Technical parameters of DATD8268-NC

|

Model |

DATD8268-NC |

|

Gas Source |

0.4~0.8Mpa dry and compressed air |

|

Air consumption |

Approx.10Ls |

|

Control signal voltage |

U=24VDCImax=0.15A |

|

Gun cleaning period |

Approx.4~5s |

|

Noise grade |

≤70db |

|

Volume of anti-splash agent |

500ml |

|

Cut wire diameter |

Carbon steel welding wire with maxdiameter of p1.6mm |

|

Spray volume ofanti-splashagent |

0~5ml/s (adjustable) |

|

Weight (body) |

24kg (pedestal included)16kg(pedestal excluded) |

Share